Printed Circuit Board Assembly

Interview with Blair Hamilton

Blair Hamilton is Vice President of Flashtalk Technology, Inc.

Tell us about Flashtalk Technology.

We are a full-service electronics contract manufacturer located in Solon, OH, about 18 miles east of Cleveland. We have been in operation since 2002. We work out of a state-of-the-art 9,000-square-foot manufacturing facility here at our Solon headquarters. We began as the manufacturing division of Timekeeping Systems, then started serving other clients as well. We split off from TimeKeeping Systems in 2005 as a separate company.

How long have you personally been doing this kind of work?

I’ve been in the electronics business for 30 years. I started as an Industrial Engineer for Reliance Electric in telecommunications. I managed several plants for them and came to Timekeeping and what is now Flashtalk in 2002.

What are customers looking for when they come to you?

That depends on the customer. Many want to maintain their cost structure and increase quality, reliability, delivery and flexibility, while freeing themselves from the burden of the large overhead investment in assembly equipment and worrying about inventory and materials. "Let that be our concern," we tell them. In other cases, they are looking for a straight cost reduction and depending on the extent of the reduction, we can usually accommodate them as well.

Often, for smaller clients with fewer in-house capabilities, we can help with the conceptual stages of a product. We can work with multiple departments within a customer’s organization, including design, purchasing, manufacturing and quality groups. In addition to basic printed circuit board assembly, we can take a product from development to prototype to manufacturing. We have helped customers with distribution services such as drop shipping, and we have handled service and repair of customers' products.

Sometimes, our involvement begins with prototype development work that may only be 10 or 100 units, but of course we can also do thousands of units if necessary. With others, typically larger clients, we might get involved in the middle of the process. We can provide resources all the way through to the box build and finished product stages, including final testing, packaging and direct shipment. We’re very flexible, and our services are driven entirely by what the client needs.

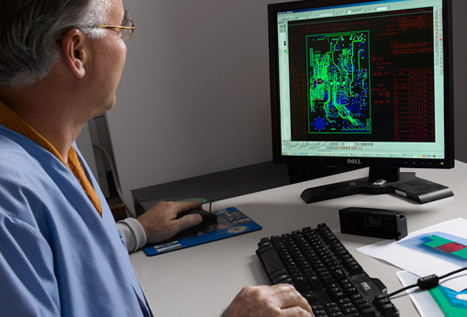

What are your manufacturing capabilities?

We offer a completely automated assembly solution for surface mount, through-hole and mixed technology circuit boards. All our capabilities are compliant with RoHS (the 2003 European Union Restriction of Hazardous Substances directive in the manufacture of electrical and electronic equipment). In addition, on the surface mount side, we provide fine pitch surface-mount and BGA placement, along with X-Ray and functional test capabilities, giving us complete process capability. Quality is assured by virtue of the fact that we meet all the critical industry standards, most notably IPC-A-610, the most widely used standard published by the IPC, the industry association for printed circuit board and electronics manufacturing service companies, covering the acceptability of electronic assemblies.

Do you serve a particular niche of the market?

We target regional manufacturers in the North American market, and our typical client is the low- to medium-volume OEM that wants a reliable provider that doesn’t miss a deadline and can do a top-notch job at a competitive cost.

What separates you from the competition?

That's easy. Quality and service.

Our sister company TimeKeeping Systems is a very high-quality supplier in a competitive market. We started as their manufacturing arm, and still do all their electronic manufacturing today. The benefit of a smaller contract electronic manufacturer is service and flexibility. The downside is that many smaller companies in this business are poorly capitalized or don't have the ability to maintain the high quality that customers are looking for. We've seen a lot of smaller contract electronic manufacturers come and go. The difference at Flashtalk Technology is that our sister company is a leader in its market. That means we'll be around as long as they are, and we'll be focused on quality as they are.

What about pricing?

Frankly, quality always comes first here. We won't sacrifice quality to win business.

But paramount in our minds, and in the minds of our clients, I believe, is our ability to achieve the quality at a competitive cost. In electronic manufacturing, your ability to manage your supply chain, coupled with your ability to have the correct assembly technologies in place, are the key factors that enable you to provide the best result for your clients. In the final accounting, though, what distinguishes us is that we’re partners with our clients, not just manufacturers but team members who have a vested interest in thinking about cost reduction in terms of the design and layout of the board itself.

I think that the way we approach sourcing in the Far East is a good example. We have a partner in Taipei who has worked exclusively for TimeKeeping Systems and Flashtalk Technology for over twenty years. Many companies order from suppliers in the Far East to save on costs, but they don't really know their suppliers. We're heard lots of horror stories that arise from this approach. In our case, our partner does the inspections, visits the suppliers, and makes sure that what we need will arrive here when we need it.

We have extensive experience in offshore sourcing and manufacturing. We directly source materials and sub-assemblies when it is economically advantageous to our client to do so — and I think we do it better than most.

What factors do you consider before deciding whether to recommend sourcing parts and assemblies offshore?

We work with our client to evaluate the pros and cons. We primarily go offshore for materials other than electronics. We source metals, molded plastics and other specialty items that go into an assembly. We often go offshore for bare circuit boards, connectors that go on a board, mechanical parts and other components that are used in the assembly.

If we get into higher volume electronics, it’s sometimes more economical to go offshore. What you want to do is make sure you’re accounting for all the costs of sourcing offshore. By the time you consider the total cost of maintaining the supply chain, and take into account the customer’s requirements for lead time and delivery, going offshore is not always such a big advantage.

What are some of the mistakes you’ve seen others in your industry make that you’re determined to avoid?

For the smaller Electronic Manufacturing Service provider, one of the biggest is underestimating the financial resources necessary to complete a job. There’s quite a bit of equipment overhead and dollar inventory investment in components required. In addition, I’ve seen how a company’s inability to manage its supply chain and maintain the customer’s schedules can doom a project, and ultimately a client relationship, to failure.

Then there’s the issue of consistent quality. I’ve seen some manufacturers take on a job without having the technological capability or engineering expertise to do the job correctly, and they let the client down.

Our relationship with TimeKeeping Systems gives us steady work that smooths out our workflow ups and downs, and gives us access to financial and other resources many EMS providers simply don't have.

Are you confident about the future of your company and the industry?

Absolutely. We’re well positioned to continue to service our existing clients and to expand our business. But one thing we’re not going to do is veer off the path that brought us to the point of widespread customer acceptance that we now enjoy.

Terms and Conditions of Sale

© Copyright 2010 by Flashtalk Technology, Inc.